Yonglong Aluminum, as a professional enterprise engaged in aluminum profile production, has always been committed to providing high-quality products and services. With the continuous growth of market demand and the continuous development of technology, Yonglong Aluminum has introduced a 3000T extruder, which is a far-reaching measure that injects new vitality into Yonglong Aluminum and provides more and better product choices for customers.

Currently, the extruded aluminum profile industry as a whole is showing a serious state of internal competition. Due to fierce market competition, many enterprises have adopted vicious competition methods to reduce costs, resulting in rampant price wars and uneven product quality.

However, as an enterprise with years of industry experience and a stable customer base, Yonglong Aluminum relies on stable and reliable product quality and good reputation. In the complex market competition, it still maintains a stable and positive development trend, with continuous growth in order volume and gradually expanding market share.

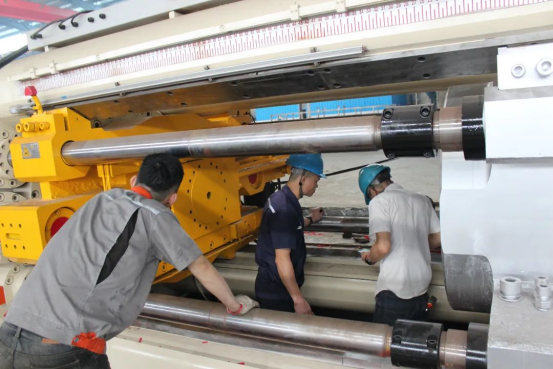

In order to alleviate production pressure and ensure timely and high-quality delivery of orders, Yonglong Aluminum has introduced this 3000T extruder. This giant machine will greatly improve production efficiency, accelerate the order production cycle, and meet the customer’s demand for fast delivery.

The extruder has the characteristics of high automation, which can achieve continuous, high-speed, and accurate production, reduce the complexity of manual operations, and improve production efficiency and product quality.

Introducing large extrusion machines can not only alleviate production pressure, but also enhance Yonglong Aluminum’s competitiveness in the market. By improving production efficiency, enterprises can better respond to market changes, meet diverse customer needs, and win more orders and cooperation opportunities. At the same time, the introduction of extrusion machines has also improved the technical level and production capacity of enterprises, laying a solid foundation for future development.

As a common metal processing equipment, extrusion machines are widely used in various industries. It can process metal materials into the desired shape through pressure, and has the characteristics of high efficiency, precision, and flexibility. In the production of aluminum alloy products, extrusion machines play a crucial role. It can extrude aluminum materials into various types of aluminum profiles, such as angle aluminum, flat plates, profiles, etc., and is widely used in fields such as construction, transportation, and electronics.

Efficient production: The extruder can extrude aluminum alloy materials into various shapes of profiles at high speed and pressure. Compared to other processing methods, extrusion machines can complete large-scale production in a shorter time, improving production efficiency.

Diversified products: Extrusion machines have flexibility and can produce aluminum profiles of different shapes, sizes, and complexities by changing molds. This enables the extruder to meet the diverse product needs of customers and provide customized solutions.

Precision and consistency: The extruder can achieve high-precision production through advanced control systems and precise mold design. It can ensure the dimensional accuracy and consistency of aluminum profiles, meeting customer requirements for product quality

Saving raw materials: The extruder can effectively utilize aluminum alloy materials and minimize waste. Through the extrusion process, complex shapes can be formed in the cross-section of aluminum profiles, reducing the amount of material required for subsequent processing.