Place of Origin: Guangdong, China (mainland)

Brand Name: Yonglong

Certification: ISO9001: 2015, ISO14001: 2015

Payment Terms: T / T or D / P at sight

MOQ: 500 kgs per model

Lead Time: 20-25 days, extra 10 days for mold production

Shipping Port: Shenzhen / Guangzhou / Foshan

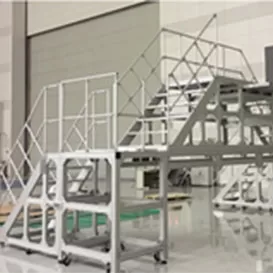

With Yonglong’s T-slot aluminum, you can gain more value compared to other welding materials. If your project requires materials that offer flexibility and versatility, you can choose our extruded T-slot aluminum extrusions, which can help you efficiently complete your projects. Anyone can create custom solutions using our T-slot aluminum profiles. Additionally, if you need to make modifications during the project, you can quickly adjust and assemble them, thanks to the sturdy and modular design of the T-slot aluminum profiles.

Yonglong’s T-slot profiles can have four or more sides, with each side featuring one or more T-slots. Through these T-slots, you can easily insert T-nuts, bolts, and other accessories, allowing you to securely and flexibly connect multiple profiles at different angles.

We offer T-slot aluminum extrusions in various sizes (2020, 3030, 4040, 4545, 5050, 6060, 8080, etc.), shapes (square, rectangular, etc.), and colors (black, white, etc.) to meet the diverse needs of your projects.

| Material Thickness (t) | 1.0-20.0 mm |

| Materiral | aluminum alloy 6060, 6061, 6082 |

| Annealing Treatment | T3-T8 |

| Color | Silver, bronze, champagne, black, (RAL series) etc. |

| Surface Treatment | Mill finish,anodized, powder coated, electrophoresis, wood grain, polished and etc. |

| Shape | Square, round, flat, oval and according to customer’s drawing. |

| Length | Normal length=6m or in customer’s order |

| Usage | Automated assembly line, production equipment workbench, automatic production line, etc. |

| Package | 1. Protective film for each profile.

2. Shrinking bag for each bundle. 3. Packed according to customer request. |

| Advantages / Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

The use of T-slot aluminum extrusions in both industrial and commercial applications is very common and is one of the lightest and most durable materials available. Through the extrusion process, we can create complex cross-sectional profiles to construct lightweight or heavy-duty T-slot frames.

Lightweight T-slot Aluminum Extrusions

Aluminum is known for its lightweight properties, weighing approximately one-third of steel. While steel may be harder and more versatile, T-slot aluminum is a great choice when your project requires a lightweight yet robust and durable material. Its superior strength-to-weight ratio makes it sturdy enough to handle most structural design and assembly applications.

Additionally, extruded aluminum T-slot require no welding and can be easily assembled and disassembled. The T-slots allow for sliding adjustments as needed, eliminating the need to clamp and weld them together like steel components.

Durable T-slot Aluminum Profiles

T-slot aluminum profiles can meet the demands of projects with stringent requirements for tensile strength, yield strength, and impact resistance, making them suitable for nearly all industrial and commercial applications. Moreover, aluminum is corrosion-resistant and does not react with moisture in the air, allowing it to be used in humid environments for extended periods. Unlike steel, you won’t have to worry about rusting over time. Anodizing further enhances its anti-corrosion properties, eliminating the need for priming and painting for protection, which saves you maintenance costs in the long run.

Furthermore, aluminum is an eco-friendly material, and when your project no longer requires its use, it can be easily recycled without causing harm to the environment.

Easy Cutting of T-slot Aluminum

Aluminum extrusions are easier to cut compared to steel, allowing you to purchase longer lengths of T-slot aluminum and cut them to the required dimensions as needed for your project. Additionally, T-slot aluminum profiles are ergonomically friendly, making them easy to maintain and suitable for various machinery and workbenches. They require minimal cleaning regardless of how long you use them. T-slot aluminum extrusions can also be paired with various extrusion connectors, such as fasteners, brackets, T-connectors, and bolt connectors.

Modular T-slot Aluminum Extrusions

In your project, all you need to do is insert connectors into the T-slot aluminum extrusions and tighten them with equipment. This is because T-slot aluminum profiles are modular and easy to work with, ensuring it won’t compromise the quality of the product. When modifications are needed, the modular advantage allows for easy adjustments.

Therefore, T-slot aluminum extrusions combine high strength, lightweight, easy cutting, modularity, corrosion resistance, and other advantages, making them widely used in various industries.